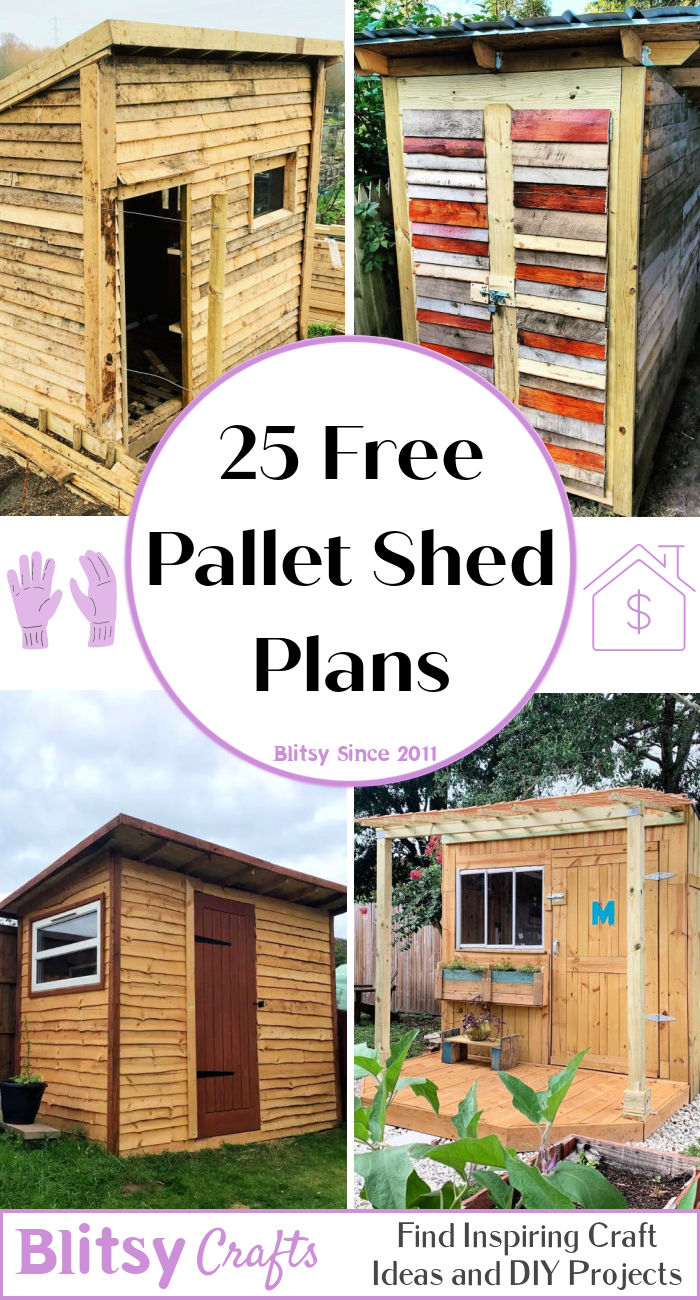

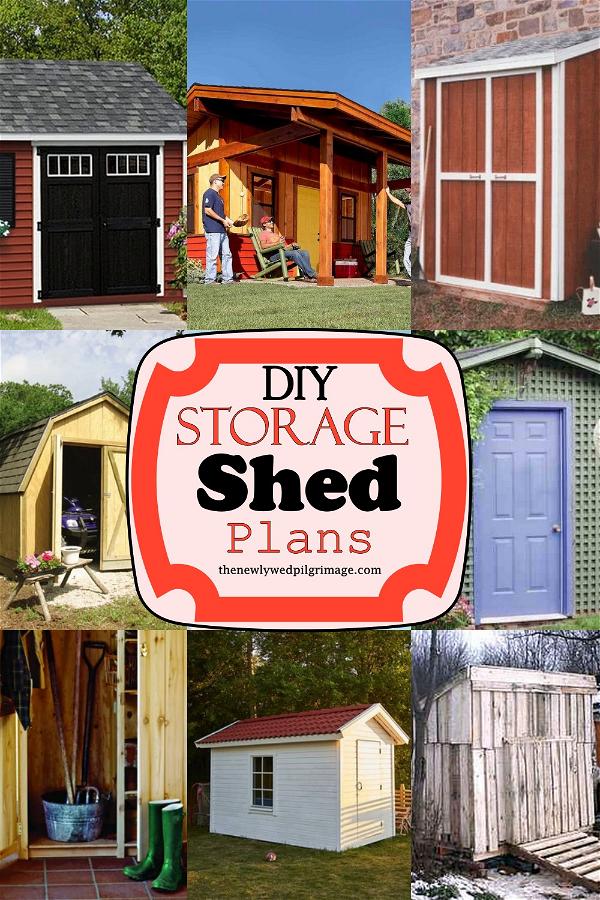

Constructing a 10x12 Pallet Shed Utilizing Reclaimed Materials

This document outlines a comprehensive guide to the construction of a 10x12 foot shed using reclaimed pallet wood. The project prioritizes sustainability and cost-effectiveness while maintaining structural integrity and aesthetic appeal. Detailed steps, material considerations, and safety precautions are included to ensure a successful build.

Phase 1: Planning and Material Acquisition

Before commencing construction, meticulous planning is crucial. This phase encompasses site selection, design finalization, and the sourcing of reclaimed materials.

Site Selection and Preparation

The chosen site must be level and adequately sized to accommodate the 10x12 foot shed, plus additional space for maneuvering during construction. Consider factors such as proximity to utilities, drainage, and potential sunlight exposure. Clear the area of vegetation, debris, and any obstructions. Leveling the ground may require excavation and the addition of a compacted gravel base for improved drainage and foundation stability.

Design Considerations

While using reclaimed pallets dictates certain design constraints, careful planning is still essential. Consider the shed's intended purpose â€" storage, workshop, or otherwise â€" to determine internal layout and features like shelving or workbenches. Develop detailed drawings, including dimensions of walls, roof structure, and doors. These drawings will serve as a roadmap throughout the construction process. Account for the varying sizes and conditions of reclaimed pallet wood when designing the frame.

Sourcing and Preparation of Reclaimed Pallets

The success of this project hinges on the acquisition of suitable reclaimed pallets. Source pallets from reputable suppliers, ensuring they are free from significant damage, rot, or pest infestation. Inspect each pallet thoroughly for broken boards, loose nails, and protruding hardware. Prioritize pallets made of strong, durable wood like pine or oak. Once acquired, dismantle the pallets carefully, removing nails and separating usable boards. Clean the boards of any dirt, debris, and loose splinters. Consider using a wire brush and pressure washer for thorough cleaning. Sort the boards by length, width, and condition, categorizing them for various structural applications.

Phase 2: Foundation and Framing

A solid foundation and robust framing are paramount for structural integrity and longevity. This phase focuses on establishing a stable base and constructing the shed's skeleton.

Foundation Construction

For a 10x12 shed, a concrete slab or a pier and beam foundation is recommended. A concrete slab provides superior stability and protection from moisture, but requires more effort and materials. A pier and beam foundation, using pressure-treated lumber for the piers and beams, is a more cost-effective and simpler alternative, particularly suitable for well-drained soil. Regardless of the chosen foundation, ensure it is level and capable of supporting the weight of the shed and its contents.

Framing the Walls and Roof

Construct the wall frames using the reclaimed pallet wood, ensuring proper alignment and squareness. Utilize longer, stronger boards for vertical studs and horizontal plates. Reinforce corners with additional bracing for added stability. Design the roof structure using a simple gable or shed roof design. Calculate the necessary rafter lengths and spacing, ensuring sufficient support for the roof’s weight and anticipated snow load. Use reclaimed boards for rafters and roof supports, reinforcing joints with appropriate fasteners.

Door and Window Installation

If incorporating doors and windows, integrate their frames into the wall framing during this phase. Use salvaged or new lumber for the frames, ensuring they are properly sized and aligned. Consider using reclaimed windows or constructing simple, functional windows from salvaged glass and reclaimed wood frames. The door could be constructed from reclaimed pallet wood or repurposed from another source. Ensure proper weather sealing around all openings to prevent drafts and moisture penetration.

Phase 3: Sheathing, Roofing, and Finishing

This phase focuses on completing the shed's exterior, ensuring weather protection and aesthetic appeal.

Exterior Sheathing

Cover the exterior wall frames with reclaimed pallet boards, arranging them for a visually appealing appearance. Overlap the boards to create a weather-resistant barrier. Consider using exterior-grade screws or nails for secure fastening. Ensure proper alignment and spacing to create a clean finish. If necessary, use additional reclaimed wood to fill gaps between pallet boards.

Roofing Installation

Apply a suitable roofing material over the completed roof structure. Reclaimed roofing materials might be available, but this is less common. Consider more readily available and durable options such as asphalt shingles or metal roofing. Ensure proper installation according to the manufacturer's instructions, creating a watertight seal to protect the shed's interior from the elements.

Finishing Touches

Apply a protective sealant or paint to the exterior surfaces to enhance durability and weather resistance. This will also enhance the appearance of the shed, creating a more uniform finish. Consider using environmentally friendly, low-VOC paints and sealants. Add any desired finishing details such as trim, molding, or decorative elements.

Phase 4: Interior Work and Final Inspections

The final phase involves the completion of interior work and a thorough inspection of the completed shed.

Interior Finishing

Complete the interior finishing as needed. This may include installing shelving, workbenches, or other desired features. Use reclaimed lumber wherever possible to maintain the project's sustainable theme. Ensure proper ventilation to prevent moisture buildup and ensure a comfortable internal environment.

Final Inspections

Conduct a thorough inspection of the completed shed, checking for any structural issues, loose components, or areas requiring additional attention. Verify the integrity of the roof, walls, doors, and windows. Address any identified deficiencies before finalizing the project. A final cleaning of the interior and exterior is a crucial step to ensure a clean and functional space.

Safety Precautions

Throughout the construction process, prioritize safety. Always wear appropriate personal protective equipment (PPE), including safety glasses, work gloves, and hearing protection. Use caution when working with power tools and sharp objects. Ensure proper ventilation when working with paints, sealants, and other potentially hazardous materials. Follow all relevant safety regulations and guidelines. If unsure about any aspect of the construction process, seek professional assistance.

Constructing a 10x12 pallet shed using reclaimed materials is a rewarding project that combines sustainability with practical utility. By following these detailed steps, and prioritizing safety and meticulous planning, you can create a durable and aesthetically pleasing structure that effectively serves its intended purpose while minimizing environmental impact.